MINOS – MInimal volume, NO pressure System, Cool Gas Generator pressurisation system for small satellites

Between November 2021 and februari 2022 a team consisting of experts from HDES Service & Engineering BV and Bradford Engineering BV investigated the feasibility of an innovative pressurisation system based on Cool Gas Generators as part of the SBIR programme of the Netehrlands Space Office. The feasibility of such a system was confirmed during the study and the road is open for further development.

Small satellites can solve many problems by making low cost communciation possible for IoT networks or better Earth Observation data and other services. This will lead to an increased amount of small satellites in Low Earth Orbit often in constellations. In order to manoeuvre these satellites in their orbits and constellations and to give them the possibility to de-orbit at the end of their lives an efficient propulsion system is required.

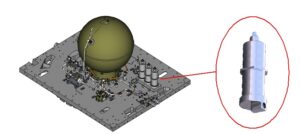

At this moment most of these satellites use blow down mono-propellant systems where a substancial part of the tank is used to contain the pressuirdation gas. This has a major impact on the size of the satellite. Therefore a small and more efficient sytsem will enable to make small satellites more efficient and smaller. It will also allow them to be launched with a minimum of pressure in the tank. This idea is called MINOS Minimal Volume, No Pressure System.

Goal

The goal of the MINOS project is to develop a smaller and more efficient pressurisation system for small satellites by applying Cool Gas Generators as a source of pressurisation gas. By using externally mounted CGGs, the volume normlaly used for pressurisation gas can be used to accomdate additional propellant.

The study combined desk research, numerical analysis and experimental work. During the desk research requirements were gathered and different propulsion systems were investigated. During the numerical system study, analyses were made on how the tank could be best re-pressurised and which size of CGG would be needed. In parellel to this work experiments with CO2 gasgenerating grains were conducted to prove their working in this application. On the basis of these results and the requiremnts, designs for two Cool Gas Generators were made to determine their sizes and mass.

Results of the feasibility study

The main result is that the study showed that such a system is feasible and that it could increase the performance of a propulsion system by 25% due to the additional propellant load and the increased avarage pressure in the tank.

Furthermore, no technical showstoppers were found that could endanger the main technical development of such a system. The composition of the CO2 producing grain was further developed and it is clear how the burn-rate and other parameters can be incluenced.

The system design and requirements showed that the size of the CGG was welll within the range that is known to HDES and that no major upscaling is needed. This was confirmed by the actual CGG designs.